IPC are similar to line taps used for overhead lines, enabling a branch connection to be made to an existing cable without stripping the insulation of the cable, and using a shear head bolt to ensure it is tightened to the correct torque. This is well established technology in some industries and prevalent in the distribution network but not generally used on the consumer’s side of the installation.

Are IPCs suitable for use on PVC consumer’s tails?

Equipment should only be used within the scope of its standard. The scope of BS EN 50483-4:2009 states that Part 4 applies to connectors used for the electrical connection of ABC and the connectors are designed to be installed on ABC defined in HD 626. PVC consumer’s tails are manufactured to BS 6004 (6181Y). Therefore, they are outside the scope of the standard and this type of IPC should not be used in consumers’ installations and on PVC consumer tails in particular.

What are the advantages of using IPC?

Connections made using IPC are less time consuming than using traditional termination methods and can be made without the need to isolate the supply. This means that their use falls within the legal definition of ‘live working’. Those who engage in live working must be able justify it and ensure the work is carried out safely.

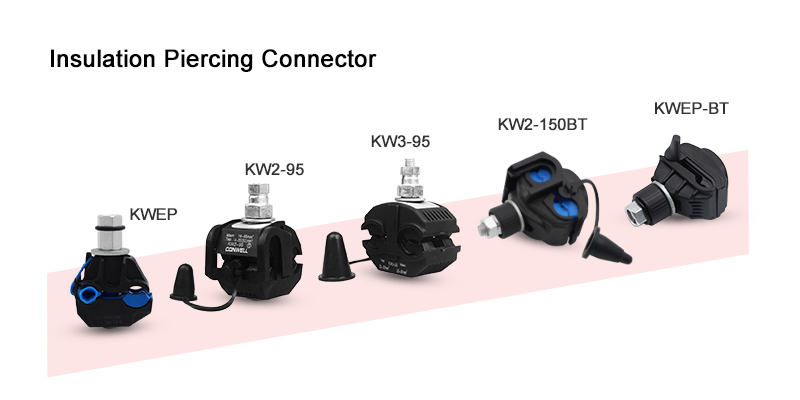

Applications of Insulation Piercing Connector

a) Insulated LV and HV lines with interconnectors provide promising insulation and robust strength for the terminal and adjacent ports.

b) To establish the connection between twisting LV network to service cables.

c) Street lights, tap off, distribution box charging, and jumper connections are the four principal applications for IPCs.

d) Also applicable in Low-voltage insulated household wire T connection; building power distribution system T connection; street lamp distribution system and ordinary cable field branch; underground power grid cable connection; line connections for lawn flower bed lighting.

Post time: Apr-14-2023