1kv Metal Tension Clamp KW116 for 16-50mm2 Aerial Cable

1kv Metal Tension Clamp KW116 for 16-50mm2 Aerial Cable

Product Introduction

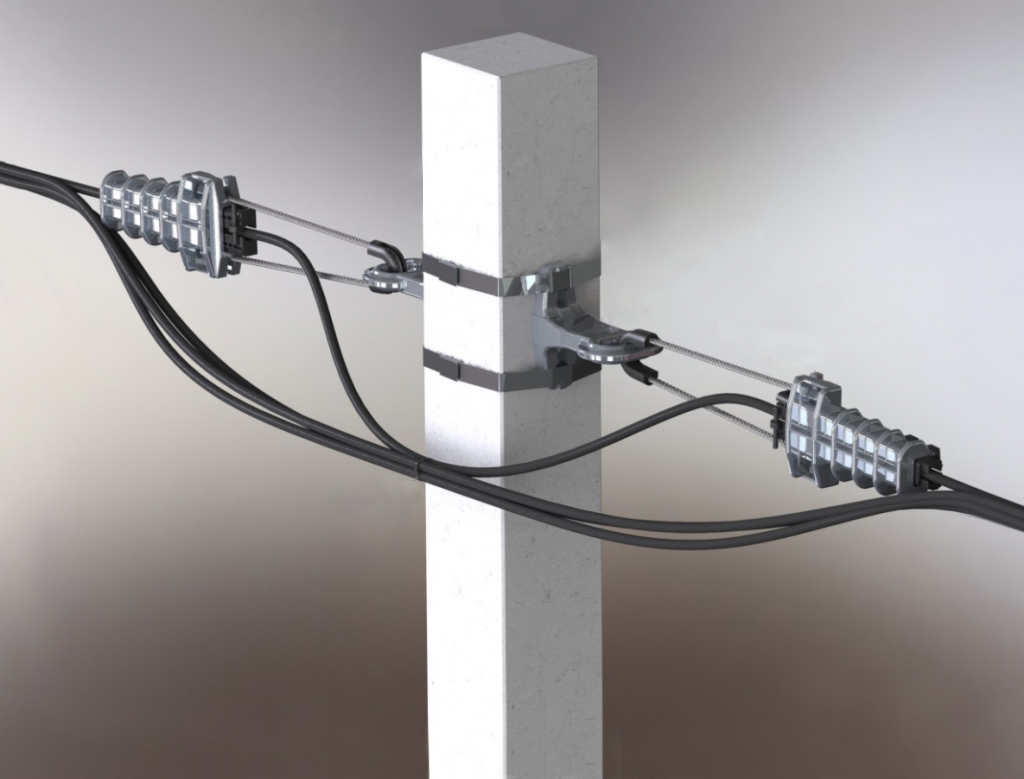

1kv Anchoring Clamp KW116 for 16-50mm2 Aerial Cable

Product introduction of 1kv Anchoring Clamp KW116 for 16-50mm2 Aerial Cable

The PA50 service clamps are designed for use with aerial cables ranging from 16mm2 to 50mm2 in cross-sectional area.

Anchoring clamps for LV AB (Low Voltage Aerial Bundled) cables are typically used in conjunction with a bracket or other supporting hardware. Their primary function is to strain the insulated or uninsulated neutral messenger or self-supported system, allowing it to terminate into transformer leads or mains for industrial or residential power supply.

Additionally, these clamps can also provide angles to a LV ABC system without causing damage to the cable's insulation. This is important for maintaining the integrity and longevity of the cable, ensuring reliable and safe electrical connections.

We are expecting become your long -term partner in China.

Product Parameter

Product Parameter of 1kv Anchoring Clamp KW116 for 16-50mm2 Aerial Cable

Materials:

Clamping Plates: Galvanized steel.

Wedges: UV and weather resistant, high strength engineering-plastic.

|

Model |

Cross-section(mm²) |

Messenger DIA.(mm) |

Breaking LoadkN) |

|

KW116 |

4x16~50 |

7-11 |

20 |

Product Feature

Product Feature of 1kv Anchoring Clamp KW116 for 16-50mm2 Aerial Cable

-- High Load Capacity: The clamp is designed to easily sustain the load of the accommodated cable size. This ensures that it can effectively support the weight and tension of the cable without any compromise to its performance or integrity.

-- Versatile Wire Compatibility: The anchoring clamp is capable of accepting a variety of wire sizes. This versatility eliminates the need for different clamp models for each wire size, simplifying inventory management and reducing the complexity of product selection.

-- Easy Wire Insertion: The spring mounting mechanism facilitates easy insertion of the wires into the clamp. This feature simplifies and expedites the installation process, saving time and effort.

-- Durability and Longevity: The anchoring clamp is specifically engineered to withstand harsh circumstances, such as environmental factors and operational stresses. This results in an extended lifespan for the clamp, enhanced safety, reduced maintenance requirements, and ultimately a lower total cost of ownership.

-- The wires are inserted easily due to the spring mounting.

Product Application